All-in-One Solutions: Explore Our Vision Laser Range and Comprehensive Services.

Whether or not you purchased your laser system from us, we provide a comprehensive range of services and ongoing support to individuals, businesses, manufacturers, and educational institutions across the UK. Our aim is to help you get the most out of your laser machine with minimal downtime and hassle.

-

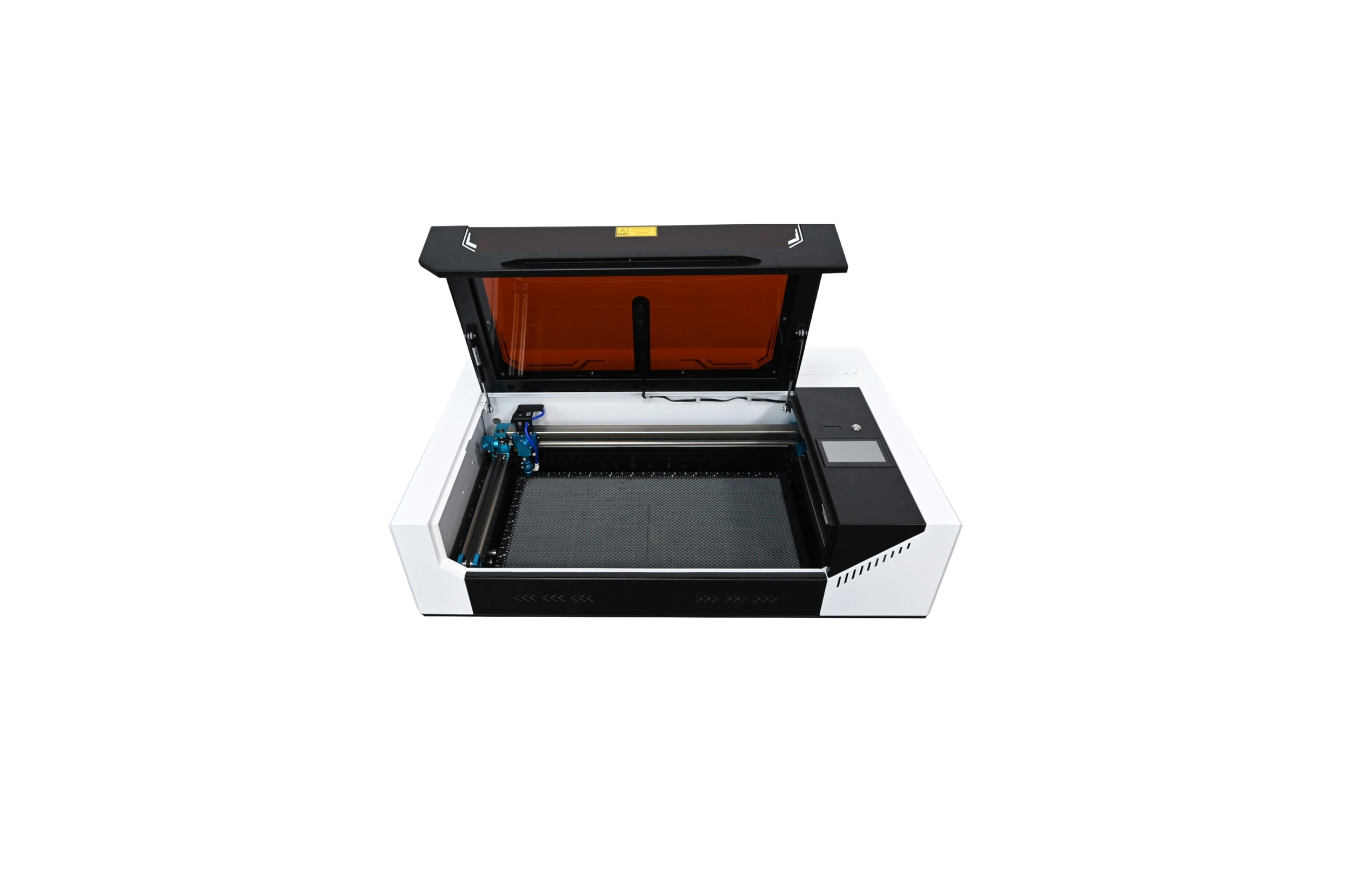

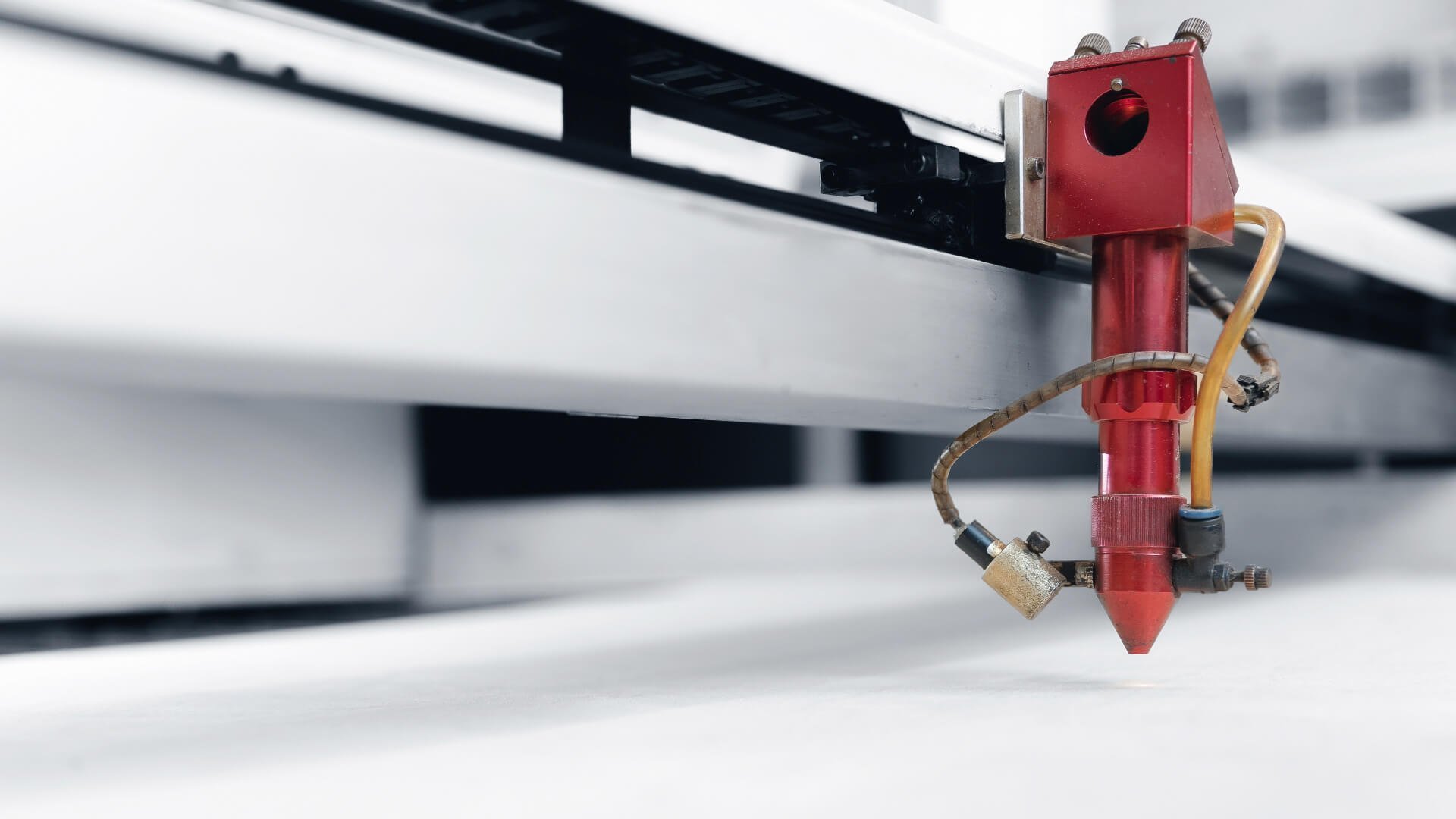

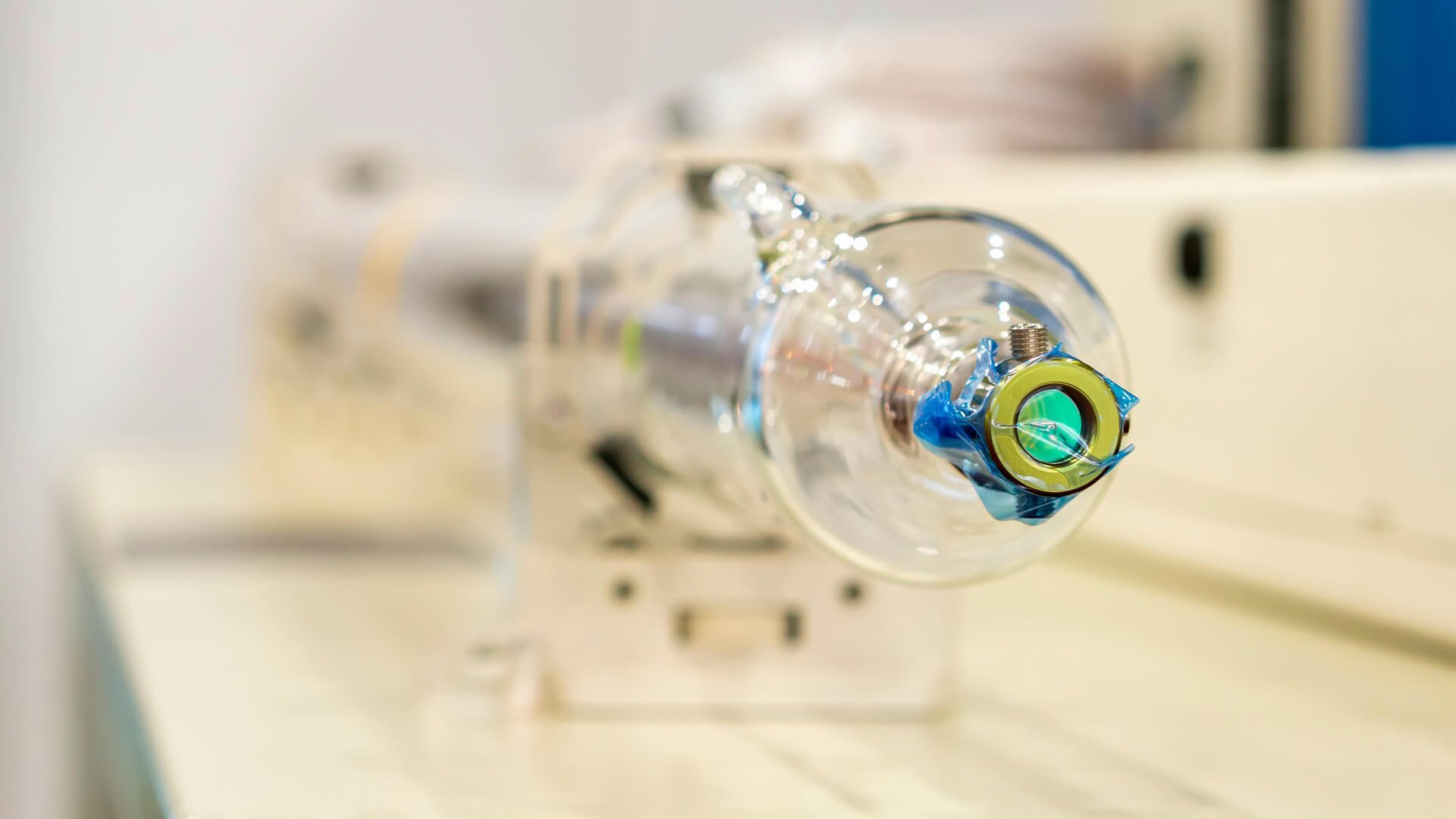

Our CO2 Laser Machines

Designed, built, and thoroughly tested in the UK, our Class 1 safety CO2 laser cutting machines are provided with installation, training, lifetime technical support and an industry-leading 2-year warranty.

-

Refurbished CO2 Lasers

Looking for an affordable laser cutter? Our thoroughly tested and refurbished systems come with a one-year warranty and lifetime technical support.

-

Laser Machine Repairs

Laser machine trouble? We offer affordable laser machine repairs, servicing, and upgrades for all CO₂ laser models, regardless of make or size, across the UK.

-

Our Service Packages

Irrespective of whether you've purchased a laser system from us, our service packages are available to all CO2 laser machine owners, providing year-round support, annual servicing, priority callouts, discounts on parts and more.

-

CO2 Laser Servicing

When was the last time you had your laser machine serviced? From routine maintenance to emergency repairs. Get back to what you do best, with minimal disruption.

-

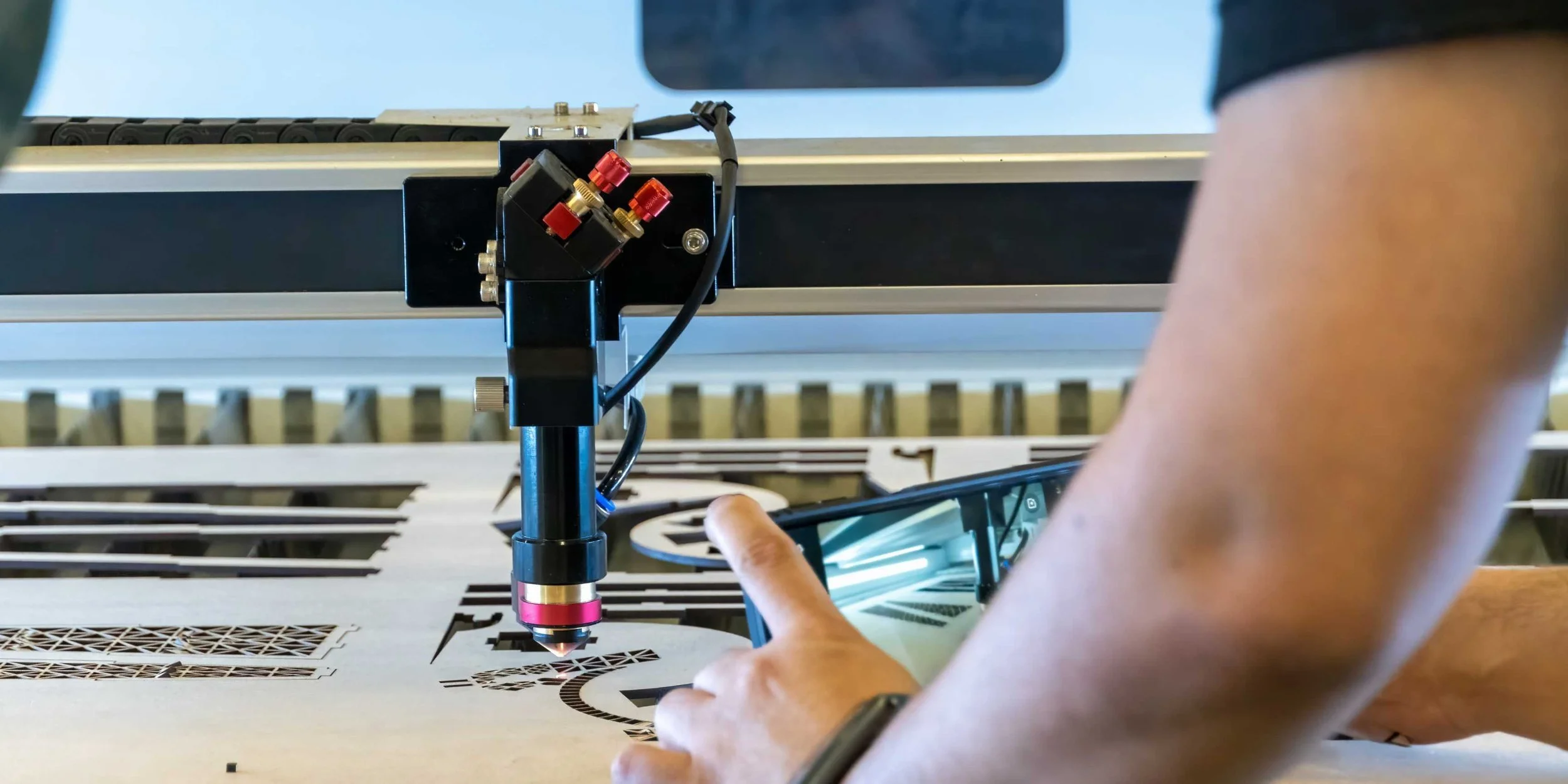

Laser Machine Training

Covering all makes and models of CO2 lasers and software, including Adobe Illustrator, CorelDRAW, Lightburn, LaserCut 5.3, and RDWorks. We offer remote software training, and on-site machine & maintenance training.

-

Laser Machine Relocation & Installation

We make upgrading, relocating, or disposing of your laser machine effortless by handling everything from collection and installation to configuration and training.

Trusted By Leading Brands

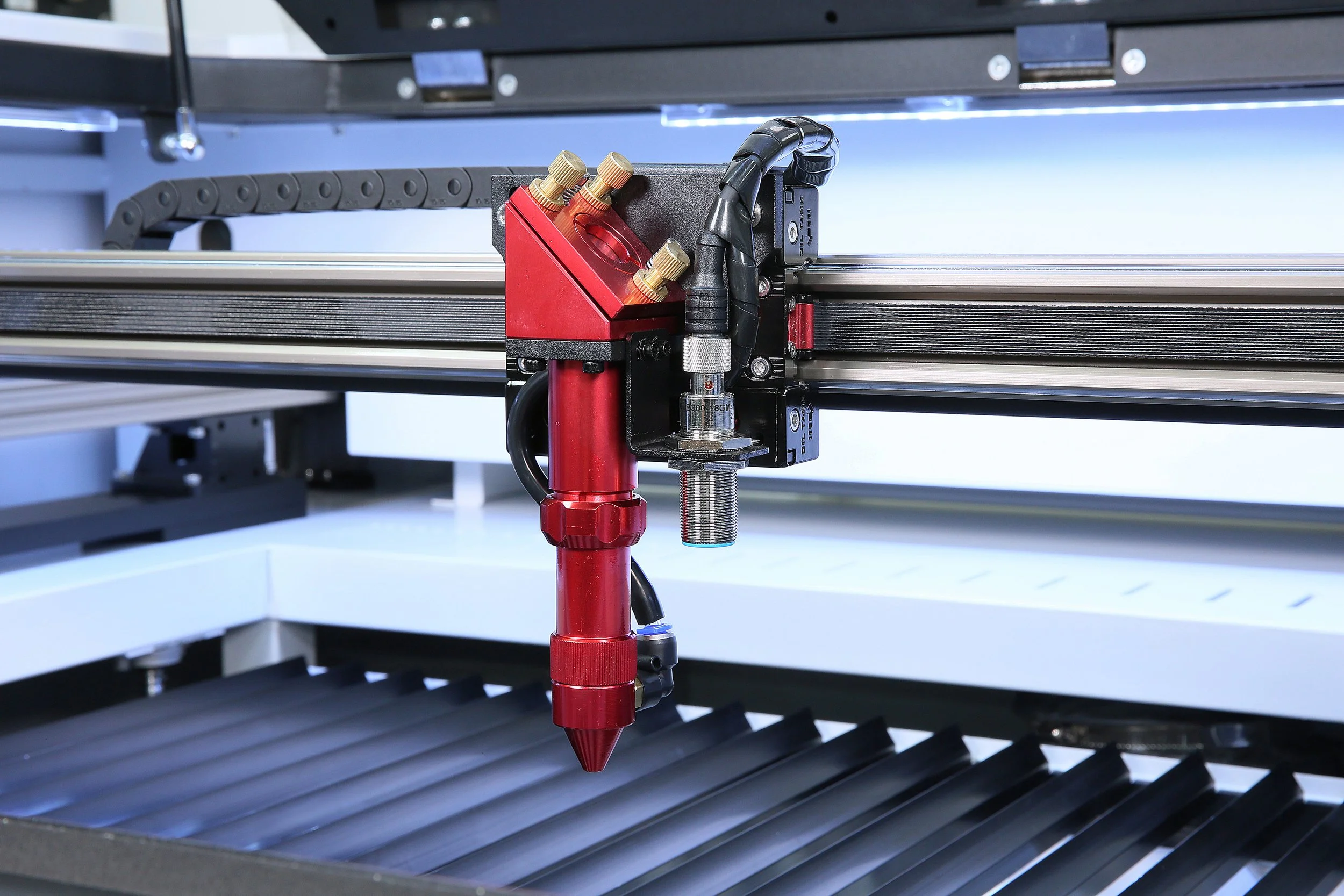

Discover our advanced CO2 lasers for precision engraving, marking, and cutting.

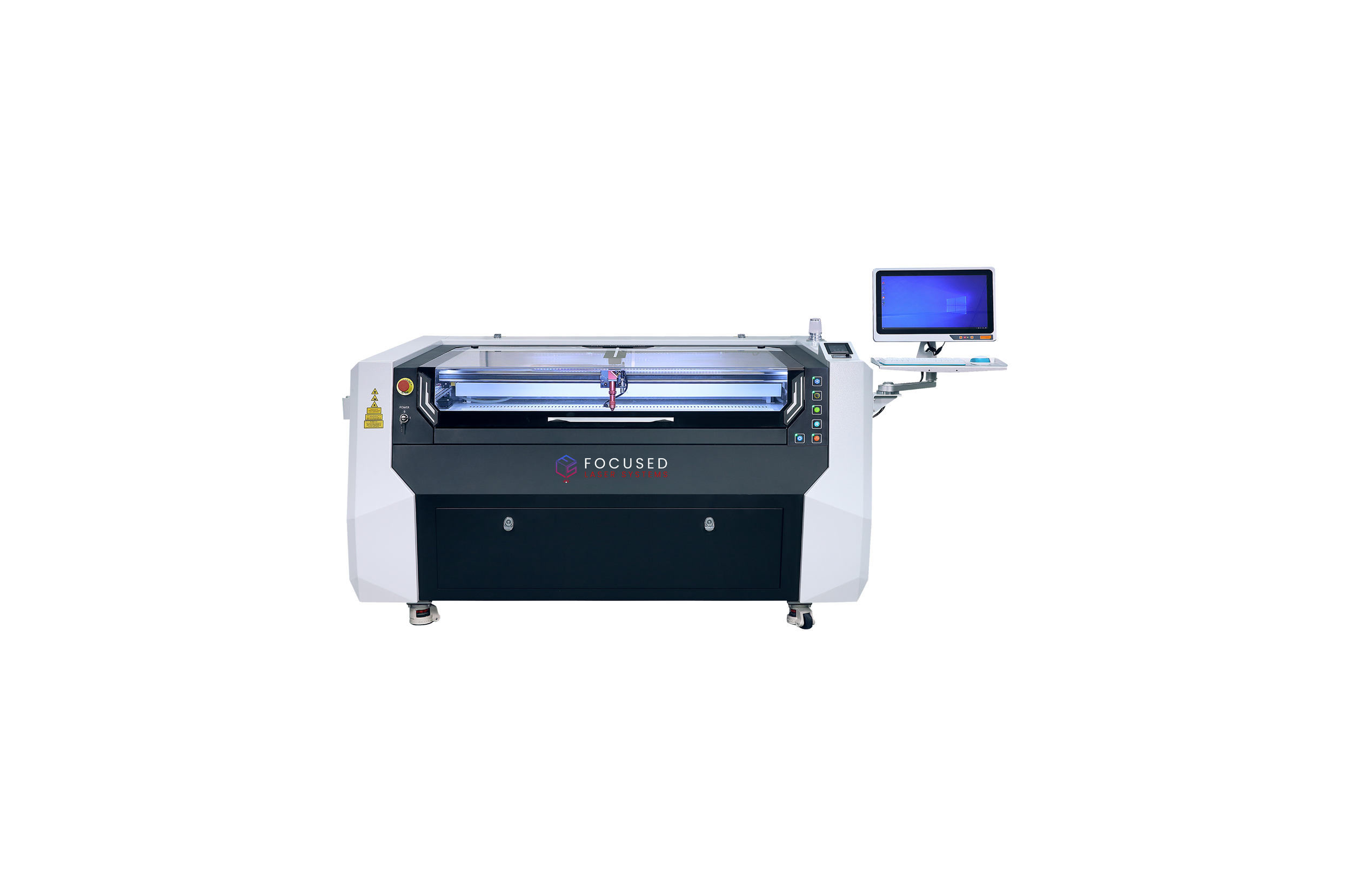

Classified as a Class 1 safety operating system, our laser cutters are the result of decades of industry knowledge at their core. All our Vision CO2 lasers are perfectly adaptable to suit your specific requirements. Additionally, we stand behind the quality of our laser machines, which is why we offer an industry-leading 2-year on-site warranty and lifetime remote technical support.

Based outside Barnstaple in Devon, we are one of the UK's leading suppliers of CO2 laser engravers committed to affordability and reliability, and the leading experts in CO2 laser machine repairs & servicing.

Our laser cutters have been designed with decades of industry expertise at their core, utilising only the highest-quality components. Available in a range of bed sizes and power levels, our laser systems are ideally suited for various applications and industries, including creatives and hobbyists, as well as schools, universities, small businesses, and manufacturing. We also provide a comprehensive range of services to streamline your journey in the world of laser technology, from laser cutter repairs and servicing to training, installation, machine relocation, and spare parts. We've got you covered.

Why Choose Focused Laser Systems?

When you purchase a laser system from us, it doesn't stop there. We offer a range of services and ongoing support, allowing you to focus on maximising the benefits of your laser machine. We understand that every client has unique needs, which is why we offer dependable technology, personalised service, and a range of benefits to streamline your journey.

Lifetime Support

We prioritise fast, efficient support without the need to submit a support ticket. Our team is on call to diagnose and resolve any issues you may be facing remotely, via video calls or remote computer access, so you can get back up and running with minimal downtime.

Extensive Warranty

With decades of industry knowledge at their core, our meticulously designed lasers withstand the test of time. We proudly offer one of the most comprehensive machine warranties in the industry, including a 2-year machine warranty and lifetime technical support.

Comprehensive Training

We're dedicated to empowering our clients with knowledge so that you can get the most out of your laser machine. From extensive training upon delivery to lifetime technical support, paired with our invaluable online resources, we've got you covered.

Service Packages

Our engineers are available to provide remote and on-site support for all your laser machine needs, regardless of the laser you have. Additionally, we offer a range of servicing packages to keep your laser in tip-top working condition, paired with extensive discounts on replacement parts.

Which materials are you looking to cut, engrave or mark on your laser cutting machine?

Find the ideal laser machine for your specific material processing needs. Our systems can handle a diverse range of materials and applications, unlocking new possibilities.

The proof is in the results. We are more than happy to conduct a test engraving on your product, allowing you to experience the exceptional quality and precision of our laser machines firsthand.

Your Questions Answered

Buying a CO2 laser engraver for the first time can feel like a minefield. Below, we've answered some of the most common questions we receive from our customers to help guide you through the process.

-

At Focused Laser Systems, we offer comprehensive coverage across the UK and Ireland—including England, Wales, Scotland, Northern Ireland, and even central London—all coordinated from our showroom in North Devon.

Our experienced engineers travel nationwide to provide delivery, installation, repairs, training, relocation, and ongoing support. If you have a specific location or requirement, please don't hesitate to reach out for tailored assistance.

-

Yes, absolutely! We’re happy to offer personalised demonstrations, giving you the chance to see our laser machines in action before making a decision. Demos are available at our North Devon showroom, or we can arrange a virtual session if visiting in person isn’t convenient.

Contact us to schedule a demo tailored to your specific needs and materials.

-

Here at Focused Laser Systems, we partner with Kennet Equipment Finance to offer competitive financing options for all our new and refurbished laser systems. These options are perfect for spreading the cost of your laser system over several years, allowing your business to reap the benefits of a CO2 laser machine.

Kennet Equipment Leasing is one of the UK’s leading providers of business equipment finance and asset leasing, enabling customers to invest in the very latest business equipment without drawing on critical working capital.

If you’d like more information on how Kennet Equipment Leasing can give your business the power to grow, please call Mark Suckley on 01675 469215.

-

At Focused Laser Systems, we proudly serve a diverse range of industries that rely on precision laser technology for manufacturing, marking, engraving, and cutting applications. Our systems are implemented across diverse sectors, including manufacturing, aerospace, automotive, medical, education, packaging, signage, jewellery, and the creative industries.

Whether you need high-performance laser equipment for production or customised solutions for specialised applications, we tailor our services to meet the unique demands of every customer we support.

-

All of our Vision CO2 laser cutters come with an industry-leading two-year warranty. At the same time, our refurbished systems are backed by a comprehensive one-year warranty, ensuring reliability and peace of mind with every purchase.

Additionally, we offer lifetime technical support you can count on—whether you need troubleshooting, routine maintenance, or expert advice. Forget support tickets—our engineers are just a phone call away to help keep your laser system running at peak performance.

For added protection, we offer optional service packages that cover ongoing maintenance and support. These plans are fully customisable to fit your equipment usage, budget, and operational needs—helping you avoid downtime and extend the life of your investment.

-

Yes, absolutely. At Focused Laser Systems, we serve customers across the entire UK. Our engineers regularly travel nationwide to deliver, install, and support laser systems, regardless of your location.

Explore, Learn, and Grow with the Latest in CO2 Laser Technology

Explore detailed case studies and stay informed on the latest advancements in laser machines, materials, and software. Gain expert insights and practical tips designed to help you harness the full power of laser technology for your business. Join us on this insightful journey and discover the limitless opportunities lasers can unlock in your industry.