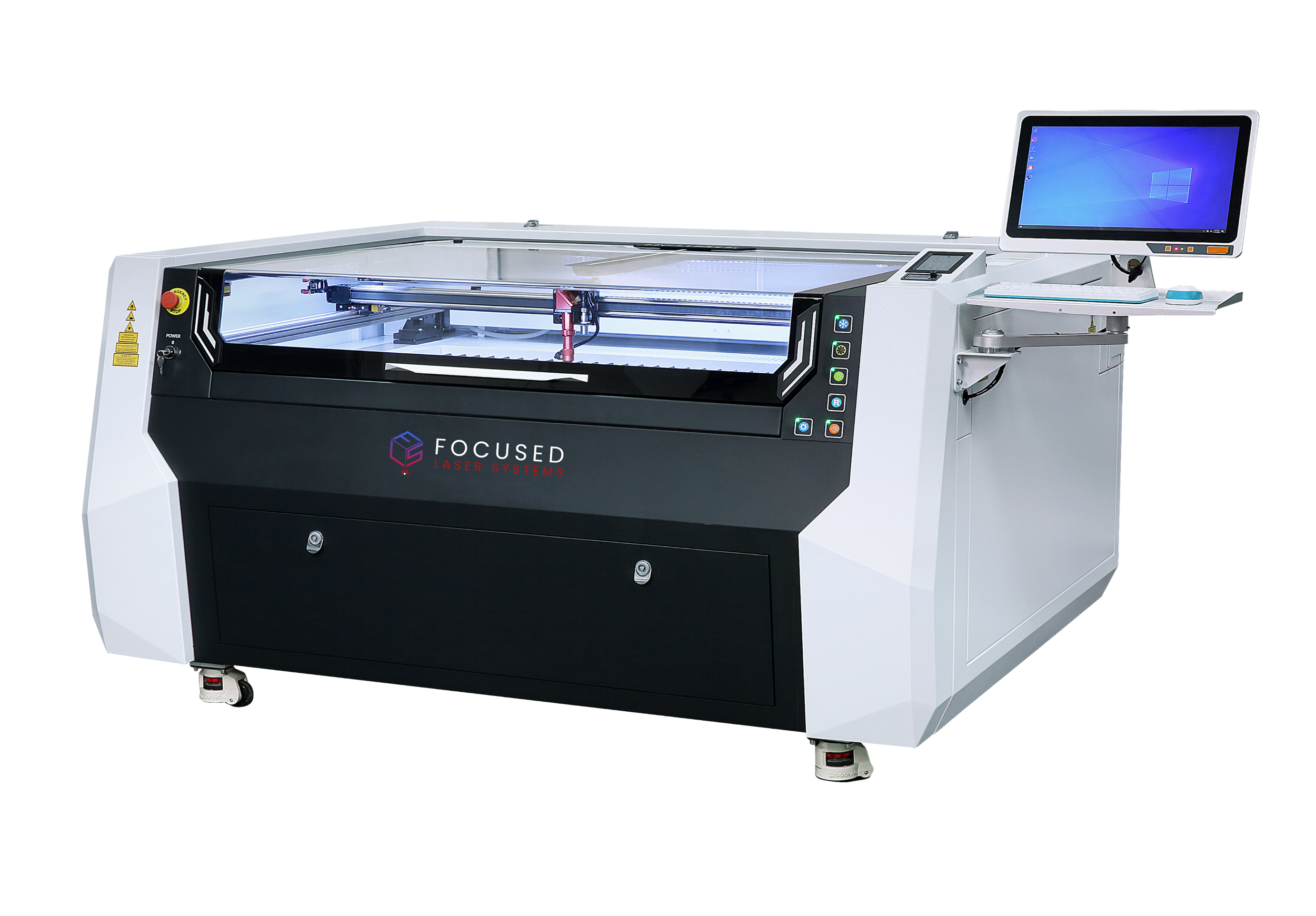

The Vision 1610 Industrial Laser Cutter

Maximum Capacity. Uncompromising Performance.

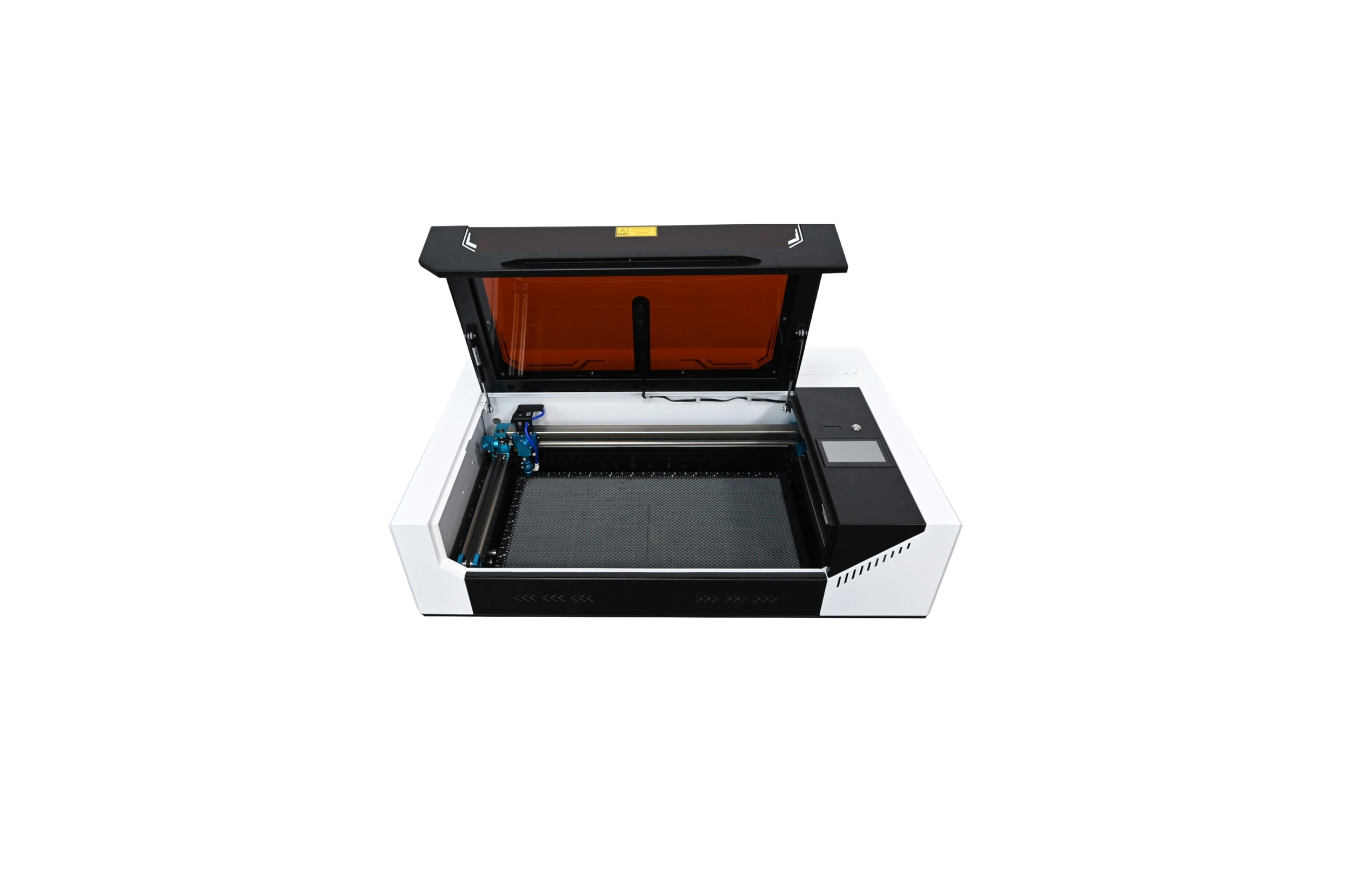

The Vision 1610 is the largest system in the Vision enclosed range, featuring an impressive 1600mm x 1000mm processing area it is engineered to accommodate large-format work without reliance on pass-through processing.

With powerful laser configurations and a rigid industrial frame, it is designed to meet the demands of high-throughput, precision-focused production.

Furthermore, as a class 1 safety laser system, our CO2 laser machines adhere to rigorous safety standards, making them a reliable choice for various environments.

Whether you choose to purchase outright or explore our diverse financing options, rest assured with our unwavering dedication to quality—each Vision laser cutter is backed by an industry-leading 2-year warranty and Lifetime technical support, providing you with peace of mind.

What Do We Provide With the Vision 1610 Industrial Laser Cutter as Standard?

Our easy-to-operate laser systems are designed to make your entry into the world of laser technology seamless and stress-free. Intuitive controls and reliable performance allow users of all experience levels to get started quickly and confidently.

2-year machine warranty

Lifetime technical support

Enclosed extraction table

Wifi & USB Connections

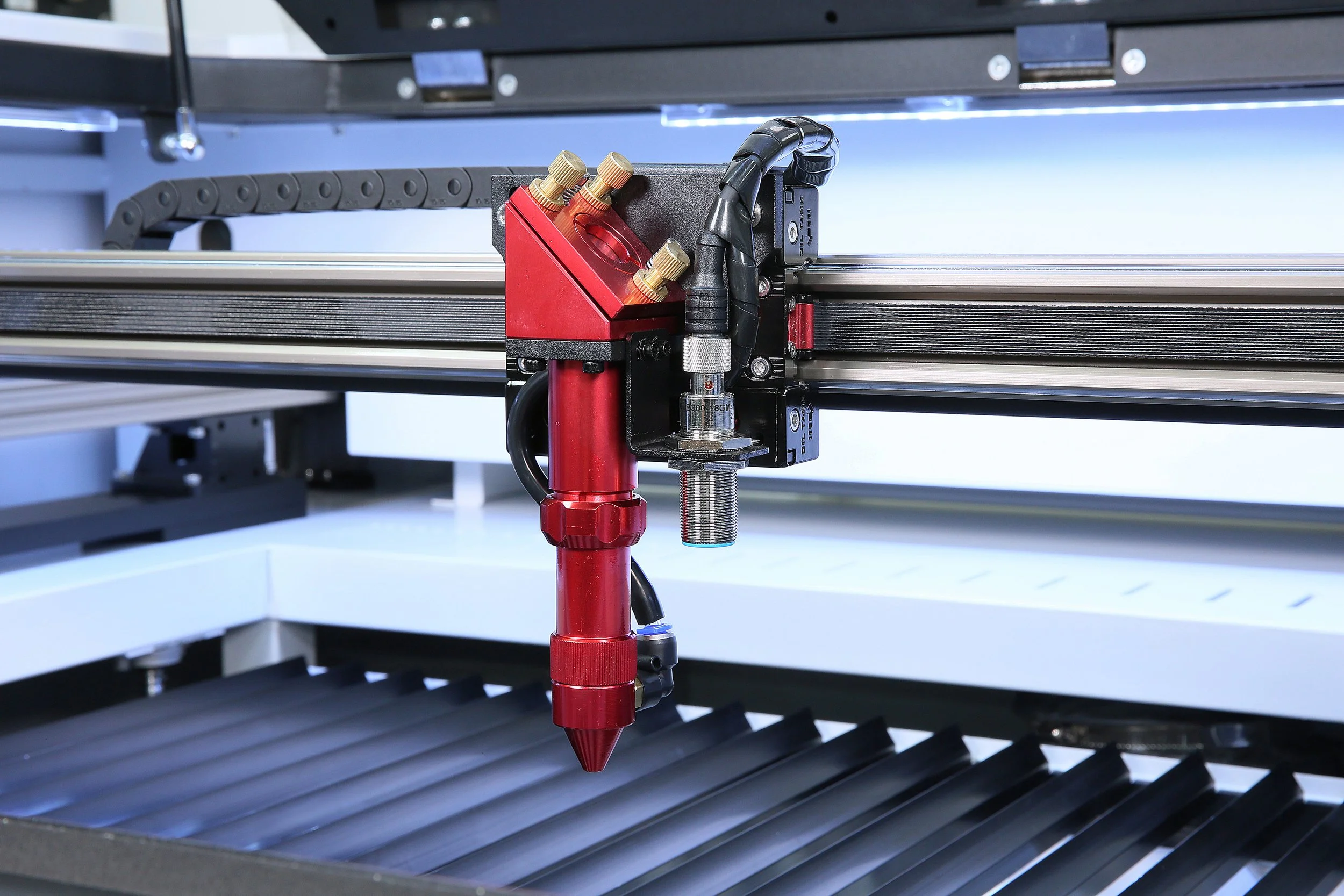

Sonar Autofocus

Red dot pointer

Lightburn software

CW-3000 / CW-5200 Chiller unit

Honeycomb laser bed

Slatted laser bed

RUIDA DSP controller

High & Low Air assisted cutting

What Materials will you be able to cut & engrave with the Vision 1610 laser machine?

Capable of processing a wide range of non-metallic materials—including glass, acrylic, wood, stone, and fabrics—CO₂ lasers have become a popular choice across a broad range of industries.

They are widely used in education, signage and display, manufacturing, product personalisation, arts and crafts, textiles, and architectural model making, thanks to their versatility and precision.

You might also be interested in our…

The proof is in the results. We are more than happy to conduct a test engraving on your product, allowing you to experience the exceptional quality and precision of our laser machines firsthand.

Backed by a 5-Star Google Reputation

-

Jo Marlow | Google Business

Jake and the team are brilliant. Jake's helped us with servicing, moving our machine, and also training. He's professional, punctual, friendly, and, above all, extremely knowledgeable. Thank you!

⭐ ⭐ ⭐ ⭐ ⭐

-

Debs Chudley | Google Business

Wow, its not often that you come across a company with service as good as this! Jake literally saved my bacon today, with prompt, helpful, efficient service and could not have done more for me.

⭐ ⭐ ⭐ ⭐ ⭐

-

Colin Farrant | Google Business

Jake and Amy are a great team. My laser is fixed and working better than when newly installed. Quick and efficient, highlty skilled and nice people to work with. Thank you Charlie Foxtrot Models.

⭐ ⭐ ⭐ ⭐ ⭐

-

Peter | Google Business

I first came across Jake at FLS when searching for my first machine. He stood out to me above the other companies I was looking to purchase from as he was so friendly, knowledgeable & super helpful in me making & taking the plunge into Laser Cutting.

⭐ ⭐ ⭐ ⭐ ⭐

-

George Ellie | Google Business

Great communication and very reliable. Went above and beyond with everything we needed, nothing seemed like too much trouble. When training was being given the support was patient and advice well explained. Look forward to seeing them again soon.

⭐ ⭐ ⭐ ⭐ ⭐

-

Chris Middleton | Google Business

Excellent customer service from start to finish. I would highly recommend Focused Laser Systems for purchasing a new laser or servicing, etc. I found Jake to be very knowledgeable, incredibly helpful, very patient, and not pushy with sales. Plus, if you visit the showroom, they offer five-star coffee.

⭐ ⭐ ⭐ ⭐ ⭐

-

Paul Boucher | Google Business

Jake has been fantastic at helping upgrade and fix a bunch of issues with our Laser Cutter - really helpful, friendly and goes above and beyond what is expected. I highly recommend Focused Laser Systems!!

⭐ ⭐ ⭐ ⭐ ⭐

-

Pete Beckley | Google Business

A friendly and professional company. From the initial inquiry Amy-Jane in sales has been brilliant with clear and prompt communication. Jake the service engineer was extremely knowledgeable, skilled and went the extra mile. He offered a variety of options for repairs, maintenance and future-proofing. I wouldn’t hesitate to recommend this company.

⭐ ⭐ ⭐ ⭐ ⭐

-

Cotton Twist | Google Business

Jake at Focused Laser Systems is the most helpful person on the planet. We'd been having some issues with our laser cutter & he took time out of his day to help. He's gone way way above and beyond to sort an interim solution, and so we will definitely be back to get help when we need to sell our machine (which is probably pretty soon) ... if only customer service was this good everywhere else across the globe.

⭐ ⭐ ⭐ ⭐ ⭐

-

Antony Hill | Google Business

An easy 5 stars. He sorted out my lasers and I couldn't be happier with the service. If you're thinking of using an engineer to fix your laser issues then you don't need to look further.

⭐ ⭐ ⭐ ⭐ ⭐

-

The Willow Workshop

I couldn't recommend Focus Laser Systems enough. Fantastic service, extremely reliable, and always happy to help with our queries. I wouldn't trust anyone else with our machine!

⭐ ⭐ ⭐ ⭐ ⭐

-

Rachel East | Google Business

Amazing service as always. Very reliable and honest with work done. Highly recommended.

⭐ ⭐ ⭐ ⭐ ⭐

-

Nicole Foxall | Google Business

Amazing Customer Care. Managed to deal with my enquiry very quickly and efficiently, will be my go-to place for Laser issues. Thank you.

⭐ ⭐ ⭐ ⭐ ⭐

-

Ruth Starsmeare | Google Business

Professional, friendly, attentive, problem-solving, and great engineers! Couldn't fault the service.

⭐ ⭐ ⭐ ⭐ ⭐

-

Liv Holman | Google Business

Incredible service, prompt and everything I wanted was no trouble! My problem was fixed and I am so pleased with it. I also found the training provided extremely helpful, would definitely use them again in the future!

⭐ ⭐ ⭐ ⭐ ⭐

-

Carly Cotterell | Google Business

Excellent service, highly recommend.

Jake always does an amazing job. Used the company twice now!⭐ ⭐ ⭐ ⭐ ⭐

-

Roy Sampson | Google Business

Jake came to my house to repair my Chinese laser cutting machine, which needed a new sensor, and also helped me with some settings, as I'm a complete novice, he was very helpful, and I can highly recommend him and his company.

⭐ ⭐ ⭐ ⭐ ⭐

-

Custom Wood Menus | Google Business

Jake replaced a damaged controller in our machine and went above and beyond to ensure that every aspect of the machine functioned as it should after the replacement.

Very reasonably priced and would highly recommend to anyone who needs a service or a tune-up.⭐ ⭐ ⭐ ⭐ ⭐

-

Karen Wilson | Google Business

Found Focused Laser services online, extremely happy with the service, Professional, friendly, very helpful, will definitely use them again, also looking forward to trying some of the courses they run.

⭐ ⭐ ⭐ ⭐ ⭐

-

Dale Medlicott | Google Business

Used Focused Laser on a number of service and repairs, always found them to be reliant and professional and have always been happy to provide advice. They certainly know their stuff and I will definitely be back again in future!

⭐ ⭐ ⭐ ⭐ ⭐

FAQ’s

-

The amount of electricity a laser machine uses depends on various factors, including the wattage of your laser tube, whether you're laser cutting or engraving a material, your extraction and cooling system, the level of maintenance on your machine, and the market cost of electricity per kWh.

CO2 laser machines, however, are relatively efficient in terms of the amount of electricity they require to operate. You can expect the estimated running costs for a small laser cutter to vary from 0.34p to 0.94p per hour, while a large-format laser cutter can cost anywhere from £1.84 to £3.47 per hour to run on average.

-

Here at Focused Laser Systems, we partner with Kennet Equipment Finance to offer competitive financing options for all our new and refurbished laser systems. These options are perfect for spreading the cost of your laser system over several years, allowing your business to reap the benefits of a CO2 laser machine.

Kennet Equipment Leasing is one of the UK’s leading providers of business equipment finance and asset leasing, enabling customers to invest in the very latest business equipment without drawing on critical working capital.

If you’d like more information on how Kennet Equipment Leasing can empower your business to grow, please call Mark Suckley on 01675 469215 or select an option below.

-

A CO2 laser machine is unable to engrave metal due to the wavelength and power of the laser beam produced by the laser tube, as well as the reflective nature of metals.

Attempting to engrave metal on a CO2 laser machine carries the inherent risk that the laser beam may reflect back up the optics and potentially cause irreversible damage to the laser tube. However, a CO2 laser can etch the top surface layer of anodised coated metals, revealing the base metal underneath.

-

The lifespan of a laser tube varies depending on the power rating, usage, and maintenance. However, on average, a CO2 laser tube can last between 2 and 5 years.

Laser tubes with proper care and moderate use often reach the upper end of this scale, ensuring longevity and consistent performance. Regular maintenance, including cleaning and alignment, can significantly extend the lifespan of a laser tube.

Visit our blog, where you'll find a range of handy tips on how to prolong the life of your laser tube.

-

You'll first want to consider the materials you're looking to process. If you're interested in laser cutting and engraving non-metallic materials, such as glass, acrylic, wood, and stone, a CO2 laser is an excellent choice.

You should also consider the size and shape of the materials you plan to process to ensure that your laser cutter's bed size is large enough to accommodate the most significant piece you intend to work with.

Additionally, you'll want to consider the power level of your laser tube (measured in watts), with higher-wattage tubes having the ability to cut or engrave thicker materials faster than lower-wattage tubes.

When choosing a suitable laser cutting machine, various factors should guide your decision, all of which we've explored in our comprehensive laser cutter buying guide. Or why not give us a call?

-

A laser cutter operates by generating a high-powered laser beam within a laser tube that contains a mixture of specific gases, including nitrogen and carbon dioxide.

The laser beam is then projected through a lens at the end of the laser tube and reflected off a series of mirrors before being refined through a focal lens onto the surface of a material.

The laser head then moves along a programmed path, heating the material's surface until it reaches its melting or evaporation point, creating a narrow and precise cut or engraving into the material.

The entire process is controlled by computer software, enabling the precise cutting of intricate designs. The laser beam can be adjusted to different power intensities, speeds, and settings depending on the material being cut or engraved, allowing for flexibility when processing a range of materials.

Located at Waytown Farm in Kentisbury, we are just 15 minutes from Barnstaple town centre with easy access via the A39. From our North Devon workshop, we actively support clients in Exeter, Plymouth, Bristol, and London, providing full coverage throughout the UK.