CO2 Laser Servicing & Repairs

Rapid response across the South West (including Exeter, Plymouth & Bristol) from our North Devon HQ.

Nationwide coverage for the rest of the UK.

Is Your Laser Cutting Machine Due for a Service?

From our showroom just outside Barnstaple in North Devon, we're the leading experts in providing professional servicing for CO₂ laser machines, whether or not they were originally purchased from us.

We recommend annual servicing to keep your laser system operating safely, reliably, and at peak performance. Routine servicing also allows wear, alignment drift, and performance changes to be identified early, helping to prevent unexpected breakdowns, reduce downtime, and extend the working life of your laser system.

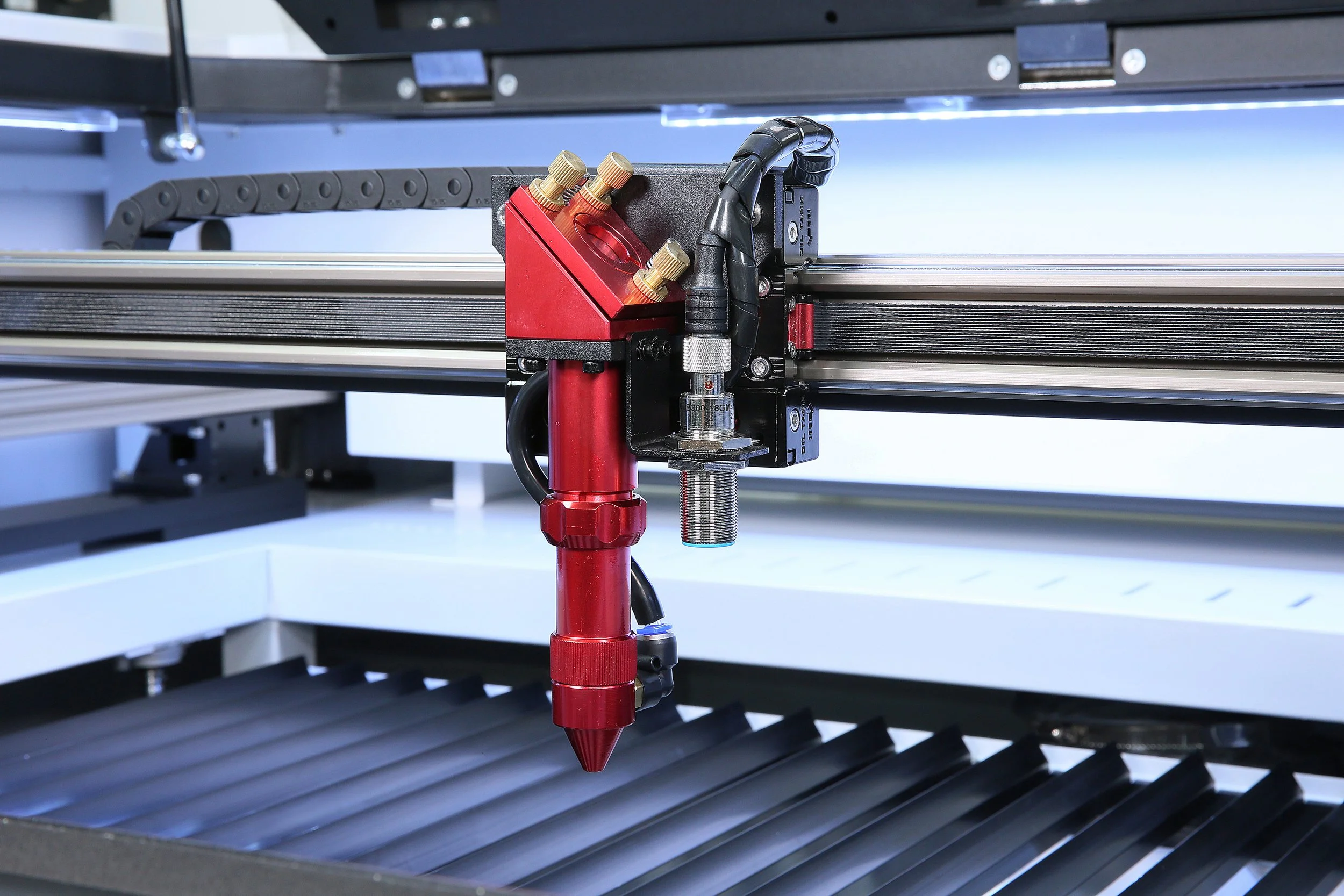

During each service visit, our engineers carry out a calibration of the motion systems, full inspection and cleaning of optics, full laser beam alignment/configuration, verification of safety interlocks and emergency stops, inspection of extraction and filtration systems, and full operational and performance testing.

These vital checks and calibrations ensure critical components are operating correctly and that the system safely continues to produce consistent, high-quality results in day-to-day use.

Each service visit is completed with a clear, easy-to-understand report detailing the work carried out and any repairs made. We’ll also highlight any recommended upgrades or parts replacements, both current and future, so you have full visibility and can plan ahead with confidence.

Want a refresher course at the same time?

Where required, servicing can also be combined with an on-site training session. This provides an opportunity to refresh operator knowledge, refine settings for your materials and applications, and improve overall workflow efficiency—ensuring both the machine and its operators are performing at their best.

What’s Included in a Service ?

-

Health Check

Laser machine health check and laser parts recommendation lists. Our engineer will conduct a comprehensive laser machine health check and notify you of any parts that may need replacement now or in the future.

-

Bed Level Adjustments

Over time, you may find your bed is unlevel due to uneven weight distribution. A level bed is crucial in ensuring you can maintain the optimal focal point and achieve perfect cutting across the cutting area of your machine.

-

Belts Check & Re-tension

Our engineers will check and re-tension your laser machine belts. This is important, as loose belts can result in the gantry losing its position or slipping during the engraving/cutting process.

-

Laser Tube Health Check

Over time, your laser tube will lose wattage and weaken as the CO2 gases naturally dissipate. Using specialist equipment, we can measure the remaining wattage of your laser tube and advise you accordingly. We can also provide glass laser tube replacements.

-

Full Laser Alignment

Our laser technicians will check all the mirrors in your laser machine to ensure the beam hits the same position, both near and far, regardless of its relation to the centre. This method will align your optics parallel to your gantry. Then, using the adjustments at the laser tube, we will align the beam to the centre of your mirrors, ensuring the laser tube is straight and level.

-

Replacement of Chiller Water

Laser chiller units are used to provide coolant to the laser tube, where heat exchange occurs, thereby cooling the laser to optimal temperatures. During your laser machine service, our engineer will replace/top-up your water chiller unit with deionised water to ensure limescale does not build up in your machine. Your laser tube will also be checked for air bubbles.

-

Check & Clean All Optics

Perfect engraving and cutting results require perfectly cleaned optics, especially when working with natural and manufactured products, which produce more debris during the cutting and engraving process. To ensure the quality of laser engraving or cutting, we provide thorough inspections and cleaning of the laser mirrors and lens.

-

Linear Rails & Bearings

Our engineer will check, clean, and lubricate all linear rails & bearings to ensure a smooth laser cutting, engraving, and marking process. Additionally, the bearings will be checked for wear to ensure they are operating as intended.

-

Proximity Sensors Check

Our engineers will conduct a series of safety checks on your laser, verifying the proximity sensors to ensure your laser head is in the correct end or home position, as well as that all safety sensors are functioning properly.

Trusted By Leading Brands

Trusted By Leading Brands

To minimise downtime, we will always endeavour to diagnose or resolve any issues you may be facing remotely before arranging a site visit, ensuring faster support and reduced disruption to your operations.

Backed by a 5-Star Google Reputation

-

Jo Marlow | Google Business

Jake and the team are brilliant. Jake's helped us with servicing, moving our machine, and also training. He's professional, punctual, friendly, and, above all, extremely knowledgeable. Thank you!

⭐ ⭐ ⭐ ⭐ ⭐

-

Debs Chudley | Google Business

Wow, its not often that you come across a company with service as good as this! Jake literally saved my bacon today, with prompt, helpful, efficient service and could not have done more for me.

⭐ ⭐ ⭐ ⭐ ⭐

-

Colin Farrant | Google Business

Jake and Amy are a great team. My laser is fixed and working better than when newly installed. Quick and efficient, highlty skilled and nice people to work with. Thank you Charlie Foxtrot Models.

⭐ ⭐ ⭐ ⭐ ⭐

-

Peter | Google Business

I first came across Jake at FLS when searching for my first machine. He stood out to me above the other companies I was looking to purchase from as he was so friendly, knowledgeable & super helpful in me making & taking the plunge into Laser Cutting.

⭐ ⭐ ⭐ ⭐ ⭐

-

George Ellie | Google Business

Great communication and very reliable. Went above and beyond with everything we needed, nothing seemed like too much trouble. When training was being given the support was patient and advice well explained. Look forward to seeing them again soon.

⭐ ⭐ ⭐ ⭐ ⭐

-

Chris Middleton | Google Business

Excellent customer service from start to finish. I would highly recommend Focused Laser Systems for purchasing a new laser or servicing, etc. I found Jake to be very knowledgeable, incredibly helpful, very patient, and not pushy with sales. Plus, if you visit the showroom, they offer five-star coffee.

⭐ ⭐ ⭐ ⭐ ⭐

-

Paul Boucher | Google Business

Jake has been fantastic at helping upgrade and fix a bunch of issues with our Laser Cutter - really helpful, friendly and goes above and beyond what is expected. I highly recommend Focused Laser Systems!!

⭐ ⭐ ⭐ ⭐ ⭐

-

Pete Beckley | Google Business

A friendly and professional company. From the initial inquiry Amy-Jane in sales has been brilliant with clear and prompt communication. Jake the service engineer was extremely knowledgeable, skilled and went the extra mile. He offered a variety of options for repairs, maintenance and future-proofing. I wouldn’t hesitate to recommend this company.

⭐ ⭐ ⭐ ⭐ ⭐

-

Cotton Twist | Google Business

Jake at Focused Laser Systems is the most helpful person on the planet. We'd been having some issues with our laser cutter & he took time out of his day to help. He's gone way way above and beyond to sort an interim solution, and so we will definitely be back to get help when we need to sell our machine (which is probably pretty soon) ... if only customer service was this good everywhere else across the globe.

⭐ ⭐ ⭐ ⭐ ⭐

-

Antony Hill | Google Business

An easy 5 stars. He sorted out my lasers and I couldn't be happier with the service. If you're thinking of using an engineer to fix your laser issues then you don't need to look further.

⭐ ⭐ ⭐ ⭐ ⭐

-

The Willow Workshop

I couldn't recommend Focus Laser Systems enough. Fantastic service, extremely reliable, and always happy to help with our queries. I wouldn't trust anyone else with our machine!

⭐ ⭐ ⭐ ⭐ ⭐

-

Rachel East | Google Business

Amazing service as always. Very reliable and honest with work done. Highly recommended.

⭐ ⭐ ⭐ ⭐ ⭐

-

Nicole Foxall | Google Business

Amazing Customer Care. Managed to deal with my enquiry very quickly and efficiently, will be my go-to place for Laser issues. Thank you.

⭐ ⭐ ⭐ ⭐ ⭐

-

Ruth Starsmeare | Google Business

Professional, friendly, attentive, problem-solving, and great engineers! Couldn't fault the service.

⭐ ⭐ ⭐ ⭐ ⭐

-

Liv Holman | Google Business

Incredible service, prompt and everything I wanted was no trouble! My problem was fixed and I am so pleased with it. I also found the training provided extremely helpful, would definitely use them again in the future!

⭐ ⭐ ⭐ ⭐ ⭐

-

Carly Cotterell | Google Business

Excellent service, highly recommend.

Jake always does an amazing job. Used the company twice now!⭐ ⭐ ⭐ ⭐ ⭐

-

Roy Sampson | Google Business

Jake came to my house to repair my Chinese laser cutting machine, which needed a new sensor, and also helped me with some settings, as I'm a complete novice, he was very helpful, and I can highly recommend him and his company.

⭐ ⭐ ⭐ ⭐ ⭐

-

Custom Wood Menus | Google Business

Jake replaced a damaged controller in our machine and went above and beyond to ensure that every aspect of the machine functioned as it should after the replacement.

Very reasonably priced and would highly recommend to anyone who needs a service or a tune-up.⭐ ⭐ ⭐ ⭐ ⭐

-

Karen Wilson | Google Business

Found Focused Laser services online, extremely happy with the service, Professional, friendly, very helpful, will definitely use them again, also looking forward to trying some of the courses they run.

⭐ ⭐ ⭐ ⭐ ⭐

-

Dale Medlicott | Google Business

Used Focused Laser on a number of service and repairs, always found them to be reliant and professional and have always been happy to provide advice. They certainly know their stuff and I will definitely be back again in future!

⭐ ⭐ ⭐ ⭐ ⭐

Laser Machine Servicing & Repairs FAQ

Whether its a routine service, or you’re dealing with performance issues, part failures, or general wear and tear, our engineers are on call to help.

Discover the answers to common questions about our repair process, response times, and what you can expect from our service.

-

No — our repair services are available to all owners of CO2 laser machines.

Our engineers have experience working with a wide array of laser cutter brands. While we can't provide an exhaustive list, some of the common brands we work with include:

Vision

Boxford

CTR Laser Cutters

Epilog Laser

HPC Laser / Laserscript

Lotus / Blu series

Mantech / LaserTech

Burghmann

Omtech

Glowforge

Opus

Thunder Laser

Universal Laser Systems

If you have a specific laser model in mind, please don't hesitate to contact us. We'd be happy to confirm whether we can assist you with its repair and maintenance.

-

Yes, we do! At Focused Laser Systems, we offer CO2 laser repairs in central London and throughout the UK. Our experienced engineers regularly travel to the capital to provide on-site diagnostics, maintenance, and repairs, ensuring minimal downtime for your equipment.

-

Common indicators include reduced cutting power, uneven engraving, unusual noises, frequent error messages, or misaligned beams. If you notice any of these issues, it’s a good idea to schedule a service before they lead to bigger problems.

-

Absolutely. We offer a comprehensive warranty on all repairs, ensuring your peace of mind and confidence in our services. The specifics of the warranty may vary depending on the nature of the repair and the components involved. A 12-month warranty covers the majority of our laser machine spare parts.

-

A telltale sign that your laser tube may be nearing the end of its lifespan is the gradual need to increase power settings or decrease machine speed to achieve consistent results, indicating a decline in the tube's power output —a natural consequence of wear and tear over time.

Our engineers carry wattage testers to accurately assess the power output of your current laser tube before recommending a replacement. This transparency empowers you to make an informed decision, ensuring you invest in a new tube only when necessary, saving you both time and money.

-

Yes, many problems can be diagnosed or resolved remotely, helping you save time and money. If remote support isn’t enough, we’ll arrange an on-site visit as soon as possible at a time that works for you.

-

Absolutely! If you’ve already sourced the necessary replacement parts, we’re happy to install them for you. However, please note that since we did not supply the parts, we’re unable to offer any warranty on them but we will guarantee our work.

-

Yes, you'll receive a comprehensive report outlining the issues identified, the actions taken, and recommendations for moving forward.

Located at Waytown Farm in Kentisbury, we are just 15 minutes from Barnstaple town centre with easy access via the A39. From our North Devon workshop, we actively support clients in Exeter, Plymouth, Bristol, and London, providing full coverage throughout the UK.