Choosing A Fume Extraction System For Your Laser Cutter

Published - September 2025

CO₂ laser fume extraction is essential to a safe workspace — protecting health, extending your machine's lifespan, and ensuring compliance with school or workplace safety regulations.

In this guide, we'll break down the two most common laser cutter fume extractors for CO₂ laser cutters: inline extraction fans and filtration units. You'll learn how each works, their pros and cons, and how to decide which option best fits your environment — whether that's a classroom, a small business workshop, a factory, or a home studio. By the end, you'll have a clear roadmap to creating a cleaner, safer, and more productive laser workspace.

Why Every CO₂ Laser Cutter Needs Proper Fume Extraction

Every time a CO₂ laser cuts or engraves, it burns through microscopic layers of material. That process releases smoke, ultrafine dust, and volatile organic compounds (VOCs). The exact fumes vary — acrylic gives off a sharp, chemical-smelling vapour, while wood produces fine dust and heavy smoke.

These by-products aren't just unpleasant. Without proper extraction, they can:

Harm health — irritating eyes, lungs, and triggering asthma or allergies.

Damage your machine — soot and residue on optics and rails shorten its lifespan.

Breach of UK Safety Regulations — failing to comply with COSHH, LEV for businesses and BS4163 for schools.

Increase fire risks — from false alarms to igniting trapped debris.

That's why fume extraction isn't optional. The good news? With the correct setup, these risks are easily avoidable.

Next, we'll explore two popular solutions — inline extraction fans and filtration units — and examine their differences, as well as how they protect both people and machines.

Inline Extraction Fans: How They Work and When to Use Them

An inline extraction fan is the simplest and most direct way to remove fumes from your CO₂ laser machine. Think of it as a high-powered ventilator: the fan pulls smoke and particles from the laser's cutting chamber and pushes them through ducting to the outside of your building.

Core Components of an Inline Fan (Motor, Ducting, Ports, Mounts)

Fan Motor: The heart of the inline extraction fan is the motorised fan itself. The motor generates airflow by spinning the fan blades, creating a negative pressure that pulls air into the unit on one side and out the other.

Ducting: Ductwork connects the inline extraction fan to the exhaust port of the CO₂ laser machine, and then from the fan to the building's outlet pipe or window. The ducting serves as the passage through which contaminated air travels from the laser to the fan. Properly sized ducting is critical to ensure efficient air movement.

Intake and Exhaust Ports: The fan will have an intake port that draws air from the duct system and an exhaust port that directs the extracted air outside. The design of these ports affects the airflow rate and efficiency of the extraction process.

Mounting Brackets: Inline extraction fans typically come with mounting brackets for secure installation in desirable locations, ensuring stability and ease of access for maintenance.

Benefits of Inline Fans (Cost, High Airflow, Low Maintenance)

Cost-Effectiveness: Inline extraction fans are typically more affordable than complex filtration systems, making them a budget-friendly option for many users.

Simplicity and Low Maintenance: With fewer moving parts and no filters to replace, inline extraction fans require minimal maintenance, resulting in lower operational costs.

Direct Air Removal: These fans provide quick and efficient removal of harmful fumes and particles directly outside, significantly improving local air quality during CO₂ laser operation.

Efficiency: Inline extraction fans can effectively manage high volumes of air, making them suitable for busy work environments with multiple laser operations.

Limitations of Inline Fans (Venting Route, Noise, Weather, Flexibility)

Installation requirements: you need an external wall or roof vent — not always practical in schools or rented units.

Noise levels: fans can generate 65–75 dB (similar to a vacuum cleaner), which can be loud and disruptive to a home, work, or classroom environment.

Weather impact: Venting outdoors can cause drafts or heat loss in winter if the ducting isn't properly sealed.

Limited flexibility: if the room has no suitable venting route, inline fans may be unworkable.

Inline systems are often the first choice for workshops, garages, and industrial units where external venting is possible. For UK schools or offices without outside access, however, filtration units (covered next) are often the safer and more practical solution.

CO₂ Laser Filtration Units: HEPA & Carbon Explained

Where inline fans push fumes directly outdoors, filtration units capture and clean the air before recirculating it back into the workspace. These self-contained systems use multiple filters to trap particles and absorb harmful gases.

Filtration System Components (Pre-Filter, HEPA, Activated Carbon)

Intake Duct: The filtration unit typically features an intake duct that connects directly to the exhaust port of the CO₂ laser machine. This ducting is designed to capture airborne contaminants as they exit the machine efficiently.

Fan or Blower: A powerful fan or blower is integral to the filtration system. This component draws the contaminated air into the unit and forces it through the filter system. The fan's power determines the unit's airflow rate, which is crucial for effective extraction.

Filtration Media: The heart of any filtration unit consists of multiple stages of filtration, each designed to target different types of contaminants:

Pre-filter: The first line of defence, these filters capture larger particles, such as dust, debris and small offcut pieces, etc, to prevent clogging of subsequent filters.

HEPA Filter: High-efficiency particulate air (HEPA) filters capture 99.97% of particles that are 0.3 microns or larger, including delicate particulate matter generated during the laser operation.

Activated Carbon Filter: Used to absorb volatile organic compounds (VOCs) and odours, activated carbon filters are crucial for preventing fumes from escaping into the air. This filter traps gaseous pollutants, making the air cleaner and more bearable.

Exhaust Outlet: After the air has been filtered, it is expelled from the filtration unit through an exhaust outlet. Depending on the unit design, this purified air can either be recirculated back into the workspace or directed through additional ventilation systems or ducting.

Benefits of Filtration Units (Health, Compliance, Quieter, Flexible Install)

Flexible installation: no need for wall vents or fixed ductwork — just position the unit near the laser and directly connect to the laser's exhaust port.

Health-focused: effective at capturing ultrafine particles and toxic gases, which is especially important in schools where student safety is paramount.

Compliance-ready: filtration units can help meet COSHH and LEV requirements in UK education and business settings.

Quieter operation: many models run at lower noise levels than inline fans.

Trade-Offs of Filtration (Filter Costs, Capacity, Maintenance Discipline)

Ongoing filter costs: Depending on the materials you cut or engrave, you'll need to replace your filters every 6–12 months, adding to your overall running expenses. Always ask for a replacement filter quote when viewing units so that you can prepare your future budget accordingly.

Reduced airflow capacity: may struggle with huge lasers or continuous industrial use.

Performance depends on maintenance: clogged or overdue filters quickly lose effectiveness, risking unsafe air quality.

Filtration units are ideal for schools, colleges, and small businesses where external venting isn't possible. They neutralise fumes at source, protecting users and those working in shared spaces.

Inline vs Filtration: Which CO₂ Fume Extraction Is Best?

Choosing between an inline fan and a filtration unit comes down to your space, usage, and priorities. Below is a quick side-by-side look at how the two solutions measure up across the factors that matter most.

| Factor | Inline Extraction Fans | Filtration Units |

|---|---|---|

| Upfront Cost | Lower purchase price (fan + ducting). | Higher initial cost (multi-stage unit). |

| Ongoing Costs | Minimal – occasional fan servicing. | Regular filter replacements (HEPA/carbon). |

| Installation | Requires an external vent (wall, window, or roof). | Plug-and-play; no external venting needed. |

| Effectiveness | Eradicates fumes from the room. | Captures particulates + VOCs; air is recirculated safely. |

| Compliance (UK) | Meets COSHH/LEV if appropriately vented. | Captures particulates + VOCs; air is recirculated safely. |

| Noise Levels | 65–75 dB (like a vacuum cleaner). | Typically quieter; varies by unit. |

| Space Requirement | Needs ducting route + clearance. | Compact footprint; sits next to the machine. |

| Maintenance | Low – check fan and duct seals. | Medium – filters must be monitored and replaced on schedule. |

| Best For | Workshops, garages, and industrial units with outdoor access. | Schools, offices, shared spaces, or sites with no external vent. |

Choosing the Best CO₂ Laser Fume Extractor for Your Space

No single extraction system fits everyone. The right choice depends on your environment, the people using the machine, and how often it's running. Here's how to think about it based on your situation:

Schools & Colleges: Safe, Compliant Solutions for Classrooms

When it comes to purchasing a laser cutting machine for a school, student safety and compliance are top priorities. UK guidance (BS 4163, COSHH, LEV testing) requires Class 1 CO₂ lasers with robust extraction systems.

Best choice: Filtration units — enclosed, safe, and easy to install without requiring modifications to the building.

Why: Filters protect students from harmful fumes, and the lack of external ducting avoids costly building work. Many units also include safety interlocks so the laser won't fire unless extraction is active.

Key tip: Budget for replacement filters in advance to avoid downtime during term time.

Small Businesses & Workshops: Uptime, Cost, and Building Constraints

Investing in a CO₂ laser can deliver significant business benefits — from increased production speed to expanded creative capabilities. However, for signage shops, craft retailers, and workshops, the priorities are uptime and cost efficiency. Downtime from poor extraction can mean lost orders and unhappy customers.

Best choice: Either option, depending on your site. Inline fans are well-suited for workshops with outside access, while filtration units are ideal for retail units or offices.

Why: Inline systems are cheaper to run in the long term, but filtration units are more effective if landlords or building restrictions prevent venting.

Key tip: Factor in the total cost of ownership (filters, ducting, laser machine maintenance package) when calculating ROI.

Home & Hobby Use: Garages, Sheds, and Spare Rooms

Space and budget are often the primary concerns. Hobby laser cutters are usually run in garages, sheds, or spare rooms.

Best choice: an inline fan if you can safely vent outdoors; alternatively, consider filtration units if you're indoors and want peace of mind.

Why: Inline fans are budget-friendly, but not always practical in rented or shared spaces. Filtration units are more expensive but let you work anywhere without complaints from neighbours about fumes.

Key tip: Always check material safety data sheets. Some plastics (like PVC) are hazardous and should never be laser cut.

Maintenance & Safety Best Practices

Plan upkeep: Build filter replacements (for filtration units) or duct cleaning (for inline fans) into your CO₂ laser maintenance checklist to maximise uptime and prevent unexpected expenses.

Match airflow to your machine: Airflow is measured in cubic metres per hour (m³/h) or cubic feet per minute (CFM), and must align with your laser's power and bed size. Always compare your extractor's airflow rating to your laser's specifications — an undersized unit simply won't be able to keep up.

Interlock safety: Where possible, use extractors with interlocks to prevent the laser from running without active extraction.

Check with your insurer: In business or education settings, ensure your extraction choice satisfies compliance and insurance requirements.

Common Laser Cutter Fume Extraction Mistakes (and How to Avoid Them)

Ignoring filter changes: A clogged carbon filter won't absorb VOCs — leading to unpleasant smells, health risks, and failed inspections.

DIY ducting shortcuts: Long, narrow, or kinked ducting runs significantly reduce airflow, making inline fans ineffective.

Cutting the wrong materials: Some plastics (like PVC) release toxic gases that no extractor can make safe — always check material safety data sheets.

Key Takeaways

Extraction is essential: Cutting or engraving with a CO₂ laser releases smoke, particulates, and VOCs that pose health, safety, and compliance risks.

Inline fans: Cost-effective, simple, and powerful for workshops with outdoor venting.

Filtration units: Safer choice for classrooms, offices, and shared indoor spaces — but require ongoing filter changes and costs.

Compliance matters: UK regulations (COSHH, LEV, BS4163 for schools) require effective fume control.

Budget beyond purchase: Always factor in ongoing costs — such as filters, duct maintenance, or servicing — as part of total ownership.

Context is key: Inline fans are suitable for industrial and hobby workshops, while filtration units are best suited for schools, SMEs, or areas where venting outside isn't possible.

Avoid shortcuts: Poor extraction setup or skipped maintenance risks health, downtime, and even insurance problems.

With the right extraction system in place — properly installed, maintained, and matched to your environment — your laser cutter can run safely, efficiently, and in full compliance.

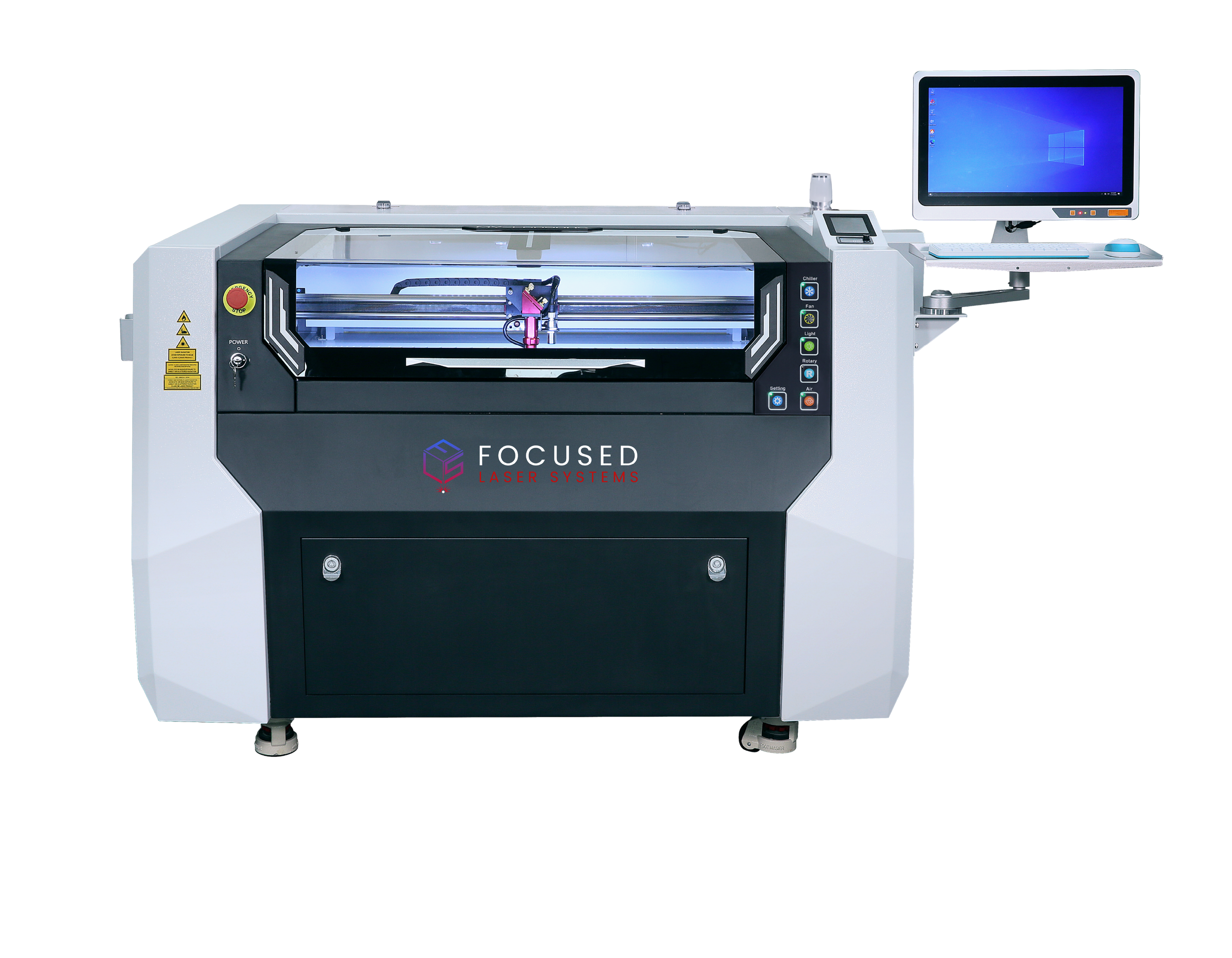

At Focused Laser Systems, we're here to guide you through every step — from assessing your workspace and recommending the right extraction system, to installation, training, and ongoing support.

We pride ourselves on being more than a supplier: we're your long-term partner in keeping your laser running safely and smoothly.

👉 Ready to explore the right extraction option for your CO₂ laser?

Contact us today to schedule a consultation, arrange a demo, or discuss installation and servicing with one of our engineers. Together, we'll ensure your workspace remains clean, safe, and future-ready.

Frequently Asked Questions (FAQ)

Do I really need an extraction system for my CO₂ laser?

Yes. Laser cutting generates smoke, particulates, and hazardous fumes. Without proper extraction, you risk health problems, equipment damage, and breaches of UK safety standards, including COSHH and LEV for workplaces and BS 4163 for schools.

Which is better: an inline fan or a filtration unit?

It depends on your setting. Inline fans are more cost-effective and efficient if you can vent them outdoors. Filtration units are better suited for classrooms, offices, or workshops without external venting — but they require regular filter replacements, resulting in ongoing costs rather than a one-time expense.

How often should filters be replaced in a laser filtration unit?

Filters typically need replacement every 6–12 months, depending on usage and the materials being processed. HEPA and carbon filters can clog over time, so follow the manufacturer's guidelines and service engineer recommendations to maintain safe air quality and stay compliant

Are filtration units compliant with UK school regulations?

Yes — filtration systems can comply with COSHH and BS 4163 standards for schools, as long as they're interlocked with the laser cutter, with filters replaced and units serviced on schedule.

Can I just vent a hobby laser cutter out of a window?

Yes — but with caution. Using a correctly sized inline fan and well-sealed ducting can be effective in a garage or shed. However, you'll want to consider neighbours, draughts, and local building regulations before implementing this setup.